Hey there, gearheads! If you're on the hunt for the best carbon fiber shafts, you've come to the right place. These bad boys are revolutionizing industries from automotive to aerospace, and let me tell ya, they're not just some fancy tech—they're game changers. In this article, we'll dive deep into what makes carbon fiber shafts so extraordinary and how they can elevate your projects to the next level. So buckle up, because we're about to get nerdy!

Now, before we jump into the nitty-gritty, let’s address the elephant in the room. Why carbon fiber shafts? Well, my friend, it’s all about performance. These shafts are engineered to deliver unmatched strength-to-weight ratios, which means you’re getting more bang for your buck without compromising durability. Plus, they look absolutely slick. Who doesn’t want to add a touch of futuristic flair to their setup?

But hold your horses, there’s more to these shafts than meets the eye. From their incredible resistance to corrosion to their ability to handle high-speed applications, carbon fiber shafts are the ultimate workhorses. So whether you're building a race car or designing a drone, understanding the best carbon fiber shafts is crucial for anyone who demands precision and reliability. Let’s get started, shall we?

Read also:Hdhub4you Your Ultimate Destination For Highquality Entertainment

Understanding the Basics of Carbon Fiber Shafts

What Makes Carbon Fiber So Special?

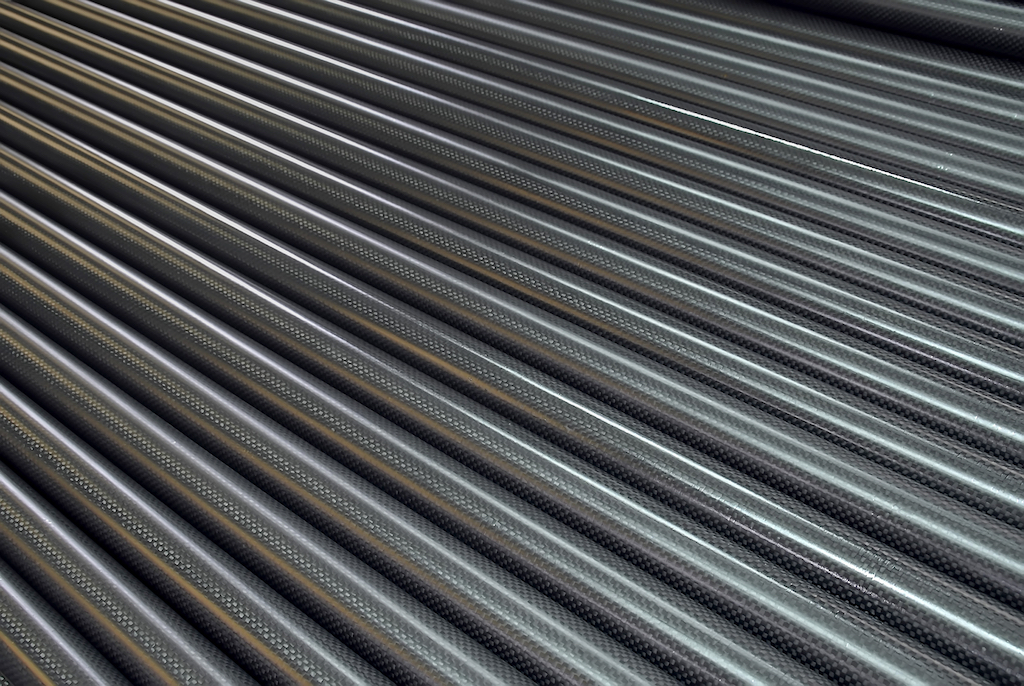

Alright, so what exactly makes carbon fiber stand out in the world of materials? Simply put, it’s a composite material made from thin fibers of carbon atoms bonded together in a crystalline formation. This structure gives carbon fiber its incredible strength and lightweight properties. When it comes to shafts, this translates to components that can handle extreme loads while remaining incredibly light.

Carbon fiber is also highly resistant to temperature changes and corrosion, making it ideal for applications where environmental conditions can be unpredictable. For example, if you’re working on a project that involves exposure to moisture or extreme heat, carbon fiber shafts will keep on truckin’ without breaking a sweat.

Why Choose Carbon Fiber Shafts Over Traditional Materials?

Here’s the deal: traditional materials like steel or aluminum have been the go-to choices for shafts for decades. But as technology evolves, so do our expectations. Carbon fiber shafts offer several advantages over their metal counterparts:

- Lightweight: Carbon fiber is significantly lighter than steel or aluminum, which can improve the efficiency of your application.

- High Strength: Despite being lighter, carbon fiber shafts are incredibly strong and can handle high torque applications.

- Corrosion Resistance: Unlike metal shafts, carbon fiber doesn’t rust or degrade over time, ensuring long-term performance.

- Vibration Damping: Carbon fiber has excellent vibration-damping properties, which can enhance the stability and accuracy of your equipment.

So if you're looking for a material that can outperform metals in terms of strength, weight, and durability, carbon fiber shafts are the way to go.

Top 10 Best Carbon Fiber Shafts for Your Projects

1. High-Performance Carbon Fiber Drive Shafts

First up, we’ve got the high-performance carbon fiber drive shafts. These shafts are designed for applications where speed and precision are paramount. Whether you’re building a race car or a high-speed industrial machine, these shafts deliver the goods. Their lightweight design reduces rotational inertia, allowing for faster acceleration and deceleration.

And let’s not forget about their sleek appearance. These shafts are not only functional but also visually stunning, making them a popular choice among enthusiasts who want to show off their builds. If you’re into racing or motorsports, these shafts are a must-have for your setup.

Read also:Hd Movies Hub Your Ultimate Destination For Cinematic Bliss

2. Aerospace-Grade Carbon Fiber Shafts

Next on our list are aerospace-grade carbon fiber shafts. As the name suggests, these shafts are built to withstand the rigors of aerospace applications. They’re engineered to handle extreme temperatures, vibrations, and loads, making them ideal for use in aircraft and satellites.

What sets these shafts apart is their unparalleled strength-to-weight ratio. In the aerospace industry, every gram counts, and carbon fiber shafts help reduce overall weight without sacrificing performance. If you’re working on a project that requires top-tier materials, these shafts are definitely worth considering.

3. Customizable Carbon Fiber Shafts

For those who need a shaft that’s tailored to their specific needs, customizable carbon fiber shafts are the way to go. These shafts can be designed and manufactured to meet exact specifications, ensuring a perfect fit for your application.

Customizable shafts offer flexibility in terms of size, shape, and material composition. Whether you need a shaft that’s longer, shorter, or has a unique cross-section, you can get exactly what you need. This level of customization is perfect for DIY enthusiasts or professionals who require bespoke solutions.

Factors to Consider When Choosing Carbon Fiber Shafts

Strength and Durability

When it comes to carbon fiber shafts, strength and durability are key factors to consider. You want a shaft that can handle the loads and stresses of your application without failing. Look for shafts that are made from high-quality carbon fiber materials and have been tested to meet industry standards.

It’s also important to consider the manufacturing process. Shafts that are manufactured using advanced techniques, such as filament winding or autoclave curing, tend to have superior strength and consistency.

Weight and Balance

Weight and balance are critical for applications where performance is a priority. Carbon fiber shafts are inherently lightweight, but it’s important to ensure that the shaft is properly balanced to prevent vibrations and ensure smooth operation.

Some manufacturers offer pre-balanced shafts, which can save you time and effort during installation. If you’re working on a project that requires precise balance, make sure to choose a shaft that meets your specific requirements.

Applications of Carbon Fiber Shafts

Automotive Industry

In the automotive industry, carbon fiber shafts are becoming increasingly popular due to their ability to improve performance and fuel efficiency. By reducing the weight of drivetrain components, these shafts allow vehicles to accelerate faster and achieve higher top speeds.

Race car teams have been quick to adopt carbon fiber shafts, as they offer a competitive edge in terms of speed and handling. Whether you’re building a street car or a race car, carbon fiber shafts can take your vehicle to the next level.

Aerospace Industry

The aerospace industry has long been a pioneer in the use of advanced materials, and carbon fiber shafts are no exception. These shafts are used in a variety of aerospace applications, from aircraft engines to satellite components.

What makes carbon fiber shafts particularly appealing to the aerospace industry is their ability to withstand extreme conditions while maintaining their structural integrity. This makes them ideal for use in environments where failure is not an option.

Common Misconceptions About Carbon Fiber Shafts

Myth: Carbon Fiber Shafts Are Too Expensive

One common misconception about carbon fiber shafts is that they’re too expensive for everyday use. While it’s true that carbon fiber shafts can be more costly upfront than traditional materials, their long-term benefits often outweigh the initial investment.

Consider the fact that carbon fiber shafts last longer, require less maintenance, and can improve the overall performance of your application. When you factor in these advantages, the cost of carbon fiber shafts becomes much more justifiable.

Myth: Carbon Fiber Shafts Are Difficult to Install

Another myth is that carbon fiber shafts are difficult to install. While it’s true that they require some specialized tools and techniques, the installation process is not as daunting as it may seem. Many manufacturers offer detailed installation guides and support to help users get the most out of their shafts.

Additionally, the benefits of using carbon fiber shafts often outweigh any installation challenges. If you’re willing to put in a little extra effort upfront, the rewards can be well worth it.

How to Maintain Your Carbon Fiber Shafts

Cleaning and Inspection

To ensure the longevity of your carbon fiber shafts, regular cleaning and inspection are essential. Start by wiping down the shafts with a soft cloth to remove any dirt or debris. Avoid using harsh chemicals, as they can damage the surface of the shaft.

Next, inspect the shafts for any signs of wear or damage. Look for cracks, scratches, or other abnormalities that could affect performance. If you notice any issues, it’s best to address them promptly to prevent further damage.

Storage and Handling

Proper storage and handling are also important for maintaining the quality of your carbon fiber shafts. When not in use, store the shafts in a cool, dry place to prevent moisture damage. Avoid stacking heavy objects on top of the shafts, as this can cause deformation or damage.

When handling the shafts, use gloves to prevent oils and dirt from transferring to the surface. This will help maintain the shafts’ appearance and performance over time.

Expert Tips for Maximizing Carbon Fiber Shaft Performance

Tuning and Optimization

For those who want to get the most out of their carbon fiber shafts, tuning and optimization are key. Start by fine-tuning the alignment of the shafts to ensure they’re running smoothly. This can help reduce vibrations and improve overall performance.

Consider upgrading other components in your system to complement the carbon fiber shafts. For example, pairing your shafts with high-performance bearings can enhance their effectiveness and extend their lifespan.

Regular Maintenance

Regular maintenance is crucial for maximizing the performance of your carbon fiber shafts. Set up a schedule for cleaning, inspecting, and lubricating the shafts to keep them in top condition. This will help prevent issues from arising and ensure that your shafts continue to perform at their best.

Conclusion: Why Carbon Fiber Shafts Are a Game Changer

So there you have it, folks! Carbon fiber shafts are truly a game changer in the world of materials. From their incredible strength-to-weight ratio to their resistance to corrosion and temperature changes, these shafts offer unparalleled performance for a wide range of applications.

If you’re looking to take your projects to the next level, investing in high-quality carbon fiber shafts is a no-brainer. Whether you’re building a race car, designing a drone, or working on an aerospace project, these shafts can help you achieve your goals and exceed your expectations.

Now it’s your turn! Have you used carbon fiber shafts in your projects? What was your experience like? Drop a comment below and let us know. And don’t forget to share this article with your friends and fellow gearheads. Together, let’s keep pushing the boundaries of what’s possible with carbon fiber technology!

Table of Contents

- Understanding the Basics of Carbon Fiber Shafts

- What Makes Carbon Fiber So Special?

- Why Choose Carbon Fiber Shafts Over Traditional Materials?

- Top 10 Best Carbon Fiber Shafts for Your Projects

- High-Performance Carbon Fiber Drive Shafts

- Aerospace-Grade Carbon Fiber Shafts

- Customizable Carbon Fiber Shafts

- Factors to Consider When Choosing Carbon Fiber Shafts

- Strength and Durability

- Weight and Balance